3D Printing For Beginners: How To Use A 3D Printer

Industrial & Scientific

Industrial & ScientificIf you've ever been curious about the fascinating world of 3D printing technology but didn't know where to start, you're in the right place. In this blog, we'll walk you through the basics of using a 3D printer, from understanding the technology and printing materials to creating your first 3D-printed masterpiece.

Whether you're a hobbyist, a student, or just eager to explore the endless possibilities of 3D printing, our expert beginner's guide got you covered. Let's dive in and unlock the wonders of 3D printers.

What is 3D Printing?

Let's start with the basics - what is 3D printing? 3D printing, also known as additive manufacturing, is a revolutionary technology that allows you to create three-dimensional objects from digital designs.

Instead of traditional subtractive methods that remove material to form an object, 3D printing adds layers of material on top of each other to build the final product. The printing process begins with a 3D model created using computer-aided design (CAD) software or obtained from online repositories. This digital model is then sent to a 3D printer, which interprets the data and starts depositing material layer by layer, gradually shaping the object.

The printing materials used can range from plastics, metals, and resins to food and even human tissue. 3D printing opens up a world of possibilities in various industries, from manufacturing and healthcare to education and design, revolutionizing the way we create and innovate.

How To 3D Print

Here's our expert comprehensive step-by-step guide for 3D printing.

Step 1: Create or Find a Design

The first step in 3D printing is to have a digital design of the object you want to create. You can either create your own design using 3D fused deposition modeling software like Tinkercad, Fusion 360, or Blender, or you can find pre-made designs on online platforms like Thingiverse or MyMiniFactory.

If you're a beginner, it's a good idea to start with simple designs before moving on to more complex ones.

Step 2: Export the STL File

Once you have your 3D design ready, you need to export it in a format that 3D printers can understand. The most common file format for 3D printing is STL (Stereolithography), which represents the surface geometry of the object.

Make sure to check your 3D modeling software's export options and choose the STL format.

Step 3: Choose Your Materials

Choosing the correct material is crucial for successful 3D printing. There are various materials available, including PLA, ABS, PETG, and more.

PLA is a popular choice for beginners because it's easy to print with and environmentally friendly. ABS is more durable but requires a heated bed and proper ventilation due to fumes. PETG combines the best of both worlds, offering strength and ease of use.

Step 4: Choose Your Parameters

Before starting the printing process, you need to set the parameters for your 3D printer. This includes adjusting the layer height, print speed, and temperature settings.

The layer height determines the thickness of each layer, while the print speed affects the printing time and quality. Temperature settings depend on the material you're using.

Check your printer's manual and experiment with different settings to find the best combination for your specific project.

Step 5: Create the Gcode

To prepare your 3D model for printing, you need to convert the STL file into Gcode. Gcode is a set of instructions that tells the 3D printer where and how to move during the printing process. Slicing software, such as Cura for PrusaSlicer, converts the STL file into Gcode.

Adjust the slicing settings, such as infill density and support structures, to suit your project's requirements.

Step 6: Print

Now that you have your Gcode ready, it's time to start the 3D printing process. Ensure your printer's build plate is leveled, and load the filament into the printer's extruder.

Upload the Gcode file to your printer, and initiate the printing process. Be patient when the printer works, as it may take several hours or more, depending on the complexity of your design.

During the printing process, keep an eye on the printer for any issues like warping, adhesion problems, or filament jams. Adjust the printer's settings as needed to achieve the desired results.

After the print is complete, allow the object to cool down before removing it from the build plate. Use caution when handling freshly printed objects, as they may still be hot or delicate.

What Can You 3D Print

3D printing has revolutionized various industries by enabling the creation of complex objects with ease and precision. The possibilities of what you can 3D print are vast and continue to expand as technology advances.

Let's explore the diverse range of items you can create using 3D printing technology:

- Rapid prototyping and rapid manufacturing - One of the primary applications of 3D printing is rapid prototyping. Engineers, designers, and manufacturers utilize 3D printing to quickly produce physical prototypes of their products. This allows them to test and iterate their designs, saving time and resources in the product development process. With 3D printing, multiple design variations can be created and evaluated to identify the most optimal solution. Rapid manufacturing is another significant application of 3D printing. It enables the production of end-use parts directly from digital designs without the need for traditional manufacturing processes like injection molding or CNC machining.

- Functional parts 3D printing is widely used in various industries to create functional parts for machines, vehicles, electronics, and more. The ability to produce intricate geometries and complex internal structures allows for the fabrication of parts that may not be feasible using traditional manufacturing methods.

- Tools 3D printing is a new way to create tools. Custom tools and jigs can be quickly designed and printed to meet specific requirements. Manufacturers can optimize their assembly lines by creating specialized tools that improve efficiency and accuracy. Maintenance teams can 3D print replacement parts for machinery and equipment, reducing downtime and costs associated with ordering spare parts. In remote or challenging environments, 3D printing offers a practical solution for producing essential tools on-site.

- Models architects, engineers, and designers use 3D printing to create detailed and precise models of buildings, products, and prototypes. These 3D-printed models allow stakeholders to visualize the final product, identify potential design flaws, and make informed decisions before actual construction or manufacturing begins.

- Art and sculptures - Artists and sculptors have embraced 3D printing as a new medium for creative expression. The technology allows them to transform digital designs into physical artworks with intricate details and unconventional shapes. 3D printing opens up endless possibilities for creating sculptures, art installations, and decorative objects that were previously challenging to achieve using traditional sculpting methods.

- Home decor and accessories - 3D printing has made its way into home decor and lifestyle products. Customized home decor items, such as vases, lamps, and picture frames, can be easily 3D printed to match individual preferences and interior styles. Additionally, personalized accessories like phone cases, jewelry, and keychains can be created with ease using 3D printing technology.

- Educational tools and toys - Educators utilize 3D printing to create interactive educational tools and models for classrooms. These 3D-printed educational aids enhance students' learning experiences by providing hands-on, visual, and tactile representations of complex concepts. 3D-printed toys and puzzles also offer engaging and fun learning opportunities for children.

- Fashion and wearable items - Fashion designers and enthusiasts are exploring the possibilities of 3D-printed clothing and accessories. Unique and avant-garde fashion pieces can be fabricated using 3D printing technology, showcasing a blend of creativity and technology in the fashion industry.

3D Printing Processes & Techniques

Here are a few 3D printing processes and techniques explained:

- Fused Deposition Modeling (FDM): FDM is one of the most popular 3D printing techniques. It involves extruding thermoplastic materials through a heated nozzle, layer by layer, to build the object.

- Stereolithography (SLA) Technology: SLA uses a liquid resin that is cured with UV light layer by layer to create highly detailed and smooth objects.

- Digital Light Processing (DLP): Similar to SLA, DLP uses a digital light projector to cure liquid resin into solid layers.

- Continuous Liquid Interface Production (CLIP): CLIP is a form of photopolymerization that continuously grows the object from a liquid resin bath, providing faster printing times.

- Material Jetting: Material jetting uses printheads to deposit layers of photopolymer material, and it can print multiple materials in a single process.

- Binder Jetting: Binder jetting involves jetting a binding agent onto a powder material to bind the layers together and create the final object.

- Selective Laser Sintering (SLS): SLS uses a high-powered laser to selectively fuse powdered materials, such as nylon or metal, into solid layers.

- Multi-Jet Fusion (MJF): MJF is a powder-based process that uses a combination of fusing and detailing agents to achieve high-quality prints.

- Sheet Lamination: Sheet lamination joins layers of material, typically paper or metal, using heat or adhesive to create the final object.

- Directed Energy Deposition: DED involves melting and depositing metal powders layer by layer using a laser or electron beam to create metal objects.

How Much Do 3D Printers Cost

The cost of 3D printers can vary significantly depending on various factors, including the type of printer, its specifications, brand, and additional features:

- Entry-Level 3D Printers: For beginners and hobbyists, entry-level 3D printers are available at more affordable prices. These printers typically have a smaller build volume and may use filament-based technology like Fused Deposition Modeling (FDM). Entry-level 3D printers can be found in the range of $200 to $500. While they may have some limitations in terms of print quality and speed, they are a great starting point for those new to 3D printing.

- Mid-Range 3D Printers: Mid-range 3D printers offer better performance, larger build volumes, and improved print quality. They are suitable for more advanced users, designers, and small businesses. These printers often feature more robust construction and may have additional functionalities like auto-bed leveling and touch-screen interfaces. Mid-range 3D printers can cost anywhere from $500 to $1500.

- Professional and Industrial 3D Printers: Professional and industrial-grade 3D printers are designed for businesses, engineers, and manufacturers who require high performance and precision. These printers are capable of handling more demanding applications and may use advanced technologies such as Stereolithography (SLA), Selective Laser Sintering (SLS), or Multi-Jet Fusion (MJF). The cost of professional and industrial 3D printers can range from $2000 to tens of thousands of dollars.

- Resin 3D Printers: Resin-based 3D printers are known for producing highly detailed and smooth prints. They use a liquid resin that cures with the help of a light source, typically a UV or laser light. Resin 3D printers come in both entry-level and professional categories, and their prices can vary accordingly. Entry-level resin 3D printers may start around $300, while high-end models can go up to $5000 or more.

- Large-Format 3D Printers: For projects that require printing larger objects or architectural models, large-format 3D printers are an option. These printers have significantly larger build volumes and are designed for industrial and architectural applications. Large-format 3D printers can be quite expensive, with prices ranging from $5000 to $20,000 or even higher, depending on their capabilities.

Keep in mind that the initial cost of the 3D printer is not the only expense to consider. Other costs may include:

- Filaments or resins: The material used for 3D printing can add to the overall cost, but there are various options available at different price points.

- Upgrades and accessories: Depending on the printer model, you may want to invest in upgrades or accessories to enhance its performance and capabilities.

- Maintenance and repairs: Like any machinery, 3D printers may require maintenance or occasional repairs, which can add to the overall cost of ownership.

Best 3D Printer:

The ELEGOO Resin 3D Printer, Mars 3 is super-high precision, and 4K HD resolution that delivers stunning 3D prints with incredible detail. According to our experts, the release of film 2.0 ensures delicate supports are well-protected, increasing the success rate for intricate models.

The upgraded light source with uniform UV light illumination takes printing accuracy to the next level. Thanks to the optimized heat sink unit, the longevity of the UV LED lights is extended. You also get a bonus of a 1-year free trial of the Chitubox Pro slicer.

Best Premium 3D Printer:

The ELEGOO Saturn 2 MSLA 3D Printer has a 10-inch 8K monochrome LCD screen that produces incredibly detailed 3D models in record time. The larger printing volume and efficient curing process allow for larger prototypes or multiple smaller models in a single batch.

Our experts find the Fresnel collimating light source ensures precise printing with a smooth surface finish. The reliable performance and odor-free printing environment make it the top premium offer for 3D printers.

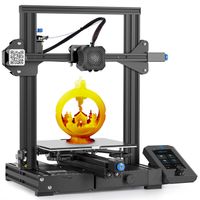

Best 3D Printer For Beginners:

Our experts find the Official Creality Ender 3 Pro 3D Printer is best for beginners with its relatively easy-to-use setup. The removable build surface plate ensures easy model removal after cooling, while the branded power supply guarantees safety from power surges.

The resume print function lets you pick up where you left off after power outages. The semi-assembled kit offers a fun educational experience in mechanical engineering and electronics. Plus, you get lifetime technical assistance and customer service.

Best 3D Printer Under $215:

Our experts find the Official Creality Ender 3 V2 self-developed silent motherboard makes printing faster, more stable, and super quiet. The UL-certified branded power supply ensures fast heating and safe operation.

Loading filament is a simple task, thanks to the rotary knob, and the 4.3" smart color screen enhances the user experience. The resume printing function saves time and reduces waste, while the carborundum glass platform ensures excellent adhesion and a smooth first layer.

3D printing is a fascinating technology that empowers you to turn your digital designs into physical objects. By following our expert guide you can start your 3D printing journey and unleash your creativity.

Remember to experiment with different materials, settings, and designs to gain a deeper understanding of 3D printing and enjoy the process.

Jonathan Levi is a writer who embraces the strange and surreal, weaving them into captivating narratives that resonate on a deeper level. His unique perspective allows him to place these extraordinary elements within a broader context.

When he's not writing, Jonathan finds solace in the world of literature. Whether it's delving into the latest news articles or immersing himself in the depths of offline books, Jonathan's thirst for knowledge and storytelling is insatiable. In Jonathan's downtime, you may catch him indulging in the thrill of a suspenseful binge-watching session. And when he's seeking a change of pace, he turns to the classic of puzzle-solving: Tetris.